Test sieves for vibrating sieve machines

Test sieves for vibrating sieve machines

Test sieves for vibrating sieve shakers

Test sieves for vibrating sieve shakers are characterized by their particularly robust construction. They are designed to withstand the intense stress of the 3D movements of vibrating sieve shakers without changing the mesh size. Unlike conventional industrial sieves, they comply with national and international standards such as DIN ISO 3310 and ASTM E11. The mesh size is precisely defined and regularly checked to ensure reproducible results in the laboratory and in quality control. They are available in mesh sizes from 20 µm to 125 mm. The sieves are suitable for both manual hand sieving and for use in vibrating sieve shakers for wet and dry sieving processes. At NEXOPART, they are available in stainless steel, wood and aluminum frame materials. In addition to the classic test sieves, NEXOPART also offers stainless steel grain and tobacco test sieves.

Test sieves for cereals – the best test tool for seed testing

Tobacco sieve – for successful quality control in tobacco processing

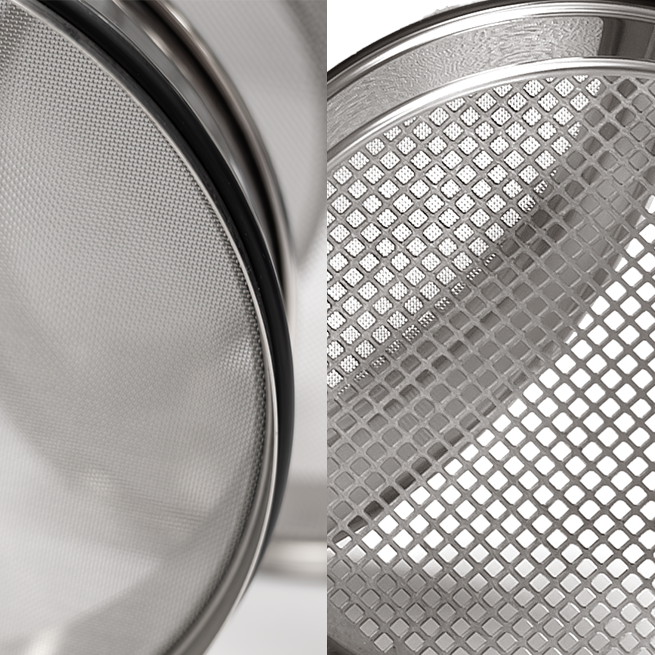

Stainless steel wire mesh or perforated plate – which is best suited for laboratory analysis?

Stainless steel wire mesh consists of woven wires that form a uniform and precise mesh. The mesh sizes are very precisely defined, making it ideal for standard-compliant analyses. The wire mesh sieve bottom is lightweight yet sturdy and fits perfectly into the sieve frame. Its large open area enables high sieving performance and rapid separation of bulk material particles. The material is corrosion-resistant and easy to clean. Test sieves with wire mesh are particularly suitable for fine to medium particle sizes and are considered the standard in laboratories.

In contrast, perforated plates are made of flat stainless steel with round or square holes punched or drilled into them. Their sieve bottom is particularly robust and can withstand high mechanical loads. Although the openings are less precise than those of wire mesh, perforated plates are well suited for coarse separation of bulk materials. The smaller open area results in a slower throughput. Thanks to the smooth surface, cleaning is very easy. Perforated plates are mainly used for coarse sieving of larger particles when stability is more important than determining fineness.

Wire cloth:

L

• Nominal sizes: 20 µm – 125 mm

• Diameters: 50 mm – 450 mm

Perforated plate with round holes:

L

• Hole sizes: 1 mm – 125 mm

• Diameters: 200 mm – 450 mm

Perforated plate with square holes:

L

• Hole sizes: 4 mm – 125 mm

• Diameters: 200 mm – 450 mm

Comparison of different test sieves for vibrating sieve shakers

Test sieves for vibrating sieve shakers can be divided into classic sieves and those for grain and tobacco. All have a stainless steel frame, which guarantees corrosion resistance and a long service life. The main differences are in the sieve bottom: Classic test sieves are covered with stainless steel wire mesh, tobacco sieves have perforated plates with elongated openings and grain sieves consist of perforated plates with round or square openings. In addition to stainless steel frames, test sieves are also available with wooden or aluminum frames. Regardless of the material, the stable construction ensures that the sieves retain their shape even under intense vibration.

1. Classic test sieves with stainless steel frames:

L

2. Properties: High corrosion resistance, very durable, precise mesh sizes according to ISO and ASTM standards

3. Application: Universal for powders, granulates and other bulk materials

4. Special feature: Ideal for vibrating sieve shakers, as they are stable and dimensionally stable

2. Test sieves with wooden frames:

L

2. Properties: Cheaper, but less robust and sensitive to moisture

3. Application: Traditional for certain natural products (e.g. flour, herbs)

4. Special feature: Particularly suitable for manual sieving, for larger quantities the NEXOPART UWL 400 H with clamping system for beechwood sieves is ideal Shop here now

3. Tobacco sieves

L

2. Properties: Specially developed for the tobacco industry and mesh sizes adapted to the structure of tobacco.

3. Application: Quality control in tobacco processing

4. Special feature: Deviations from the norm are possible due to industry-specific characteristics. Tobacco is analysed in a variety of forms, such as large leaves or small tabacco snippets.

4. Grain sieves:

L

2. Properties: Large mesh sizes for coarse separation, less precise than laboratory sieves, complies with DIN ISO 3310-2 and also complies with the ISO 5223 standard for perforated plates

3. Application: Agriculture, Seed Testing

4. Special feature: They are available with perforated plates with round holes, for example for rice grains, or with perforated plate with square holes for cereal grains.

5. Aluminum sieves:

L

2. Properties: Perfect for coarse bulk material such as stones, complies with the EN 933-3 standard and for manual sieving, not for vibrating test shakers

3. Application: special application to test the flatness of rock samples such as building materials, stones and soils

4. Special feature: Control measurement after mechanical sieving to check the length-width/ flatness ratio of aggregates

Errors that are easy to avoid when working with test sieves in the laboratory

Amplitude set too high:

L

Neglected cleaning and maintenance of the test sieves:

L

Drying test sieves:

L

No standardization of environmental conditions:

L

Accessories for test sieves of the vibrating sieve shakers:

NEXOPART offers a wide range of accessories for test sieves that have been specially developed for use on vibrating sieve shakers. Here you will find a selection of these products.

Your advantages at NEXOPART:

FAQ about test sieves for vibrating sieve shakers

What are test sieves for vibrating sieve shakers used for?

L

What is the ideal sample weight for test sieves?

L

What factors affect the accuracy of test sieves?

L

• Standards such as ISO 3310 or ASTM specify permissible deviations.

• For wire mesh, tolerances are ±2 to 5% of the nominal diameter.

• Perforated plates often have larger tolerances of ±5 to 10% because their production is less precise.

2. Wire diameter and fabric tension:

• Uneven or too thin wire will change the actual mesh opening.

• Voltage losses due to aging or mechanical stress affect the mesh size.

3. Frame deformation:

• The high forces of vibrating sieve shakers can deform the frame and thus change the sieve surface.

4. Wear and abrasion:

• Abrasion leads to an increase in the mesh size over time, which causes systematic deviations.

5. Particle behavior:

• Agglomeration, electrostatic charge or moisture impair the separation behavior.

6. Calibration and test Methods:

• Regular checks with test specimens or optical measuring systems are essential.

• Errors in calibration increase the uncertainty of the results.

What measurement uncertainties typically occur during analysis with test sieves?

L

• ±2 bis 5 % for wire mesh

• ±5 bis 10 % for perforated plates

In the entire sieve analysis, including sample preparation and handling, the uncertainties are usually in the range of ±5 to 10% in the particle size distribution.

The vibration parameters also influence the result:

• A too high amplitude or frequency can lead to over- or underclassification of the particles.