Dynamic Image Analyzer

Dynamic image analysis: fully automated determination of particle size and shape of your sample with the NEXOPART CPA 2-1

Dynamic image analysis (DIA) has established itself as a key technology in modern particle analysis. This method is becoming increasingly important, particularly in the chemical industry and engineering – wherever precise information about particle size, shape and distribution is essential for quality assurance and process optimization. In the field of dynamic image analysis, NEXOPART offers the CPA 2-1 for use in the laboratory and the CPA 2-1 ONLINE for use in ongoing production processes.

Application examples - Industries with high demands on dynamic image analysis

Dynamic Image Analysis (DIA) is specially designed for dry, free-flowing and non-agglomerating bulk materials such as fertilizers, abrasives, sand, coal, food, pharmaceuticals, plastics, seeds, ceramics or glass. Precise particle characterization is of great importance in numerous industrial sectors, including:

- Feed industry: Control of feed types and qualities. A specific grain size distribution is important for good feed intake; customers want individual mixtures and no damage to the feed flakes

- Chemical industry: Shape analysis for detecting defective products in the manufacture of, for example, catalysts, plastic granulates, etc.

- Blasting abrasive industry: Shape measurement, measurement of material wear, e.g., steel or plastic balls.

- Wood industry: Length and width are important process parameters for granulates and pellets, for example.

- Fertilizer industry: To obtain information about ingredient separation and moisture retention.

- Food industry: Influence on solubility, e.g., of sugar or salt.

Increase your efficiency with NEXOPART – your advantages:

Do you have questions about dynamic image analysis and other Nexopart products? Contact us.

What is dynamic image analysis?

L

Measuring range, calibration, and software of the CPA 2-1 from NEXOPART:

L

Restrictions: The CPA 2-1 is not suitable for:

1. Materials such as flour, cement, gypsum, etc.

2. Materials that are normally analyzed with laser diffraction devices (CPA is not designed as an alternative to laser diffraction technology)

3. Mechanical separation

4. Color detection

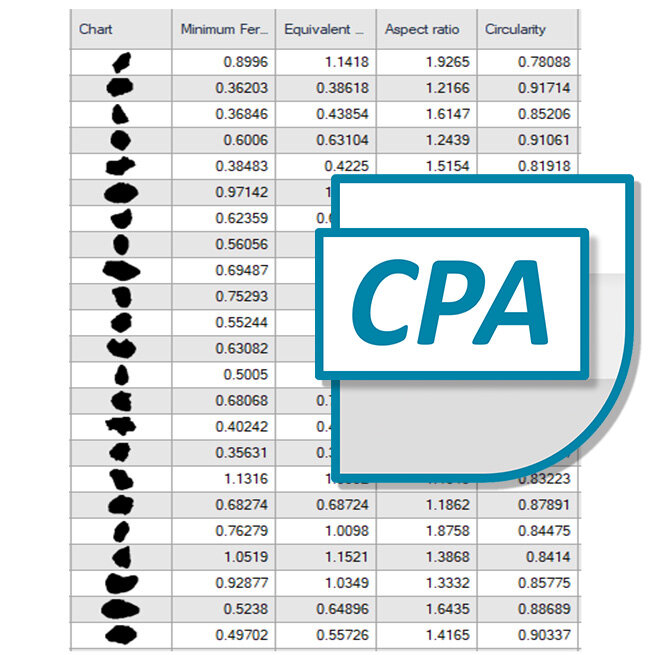

Measuring range: 20 µm to 30 mm (125 µm to 20 mm comfort zone), determination of Feret diameter

Materials: Frac sand, foundry sand, sand in general, coal, iron pellets, activated carbon, fertilizer, potassium carbonate, phosphate, shot blasting, sugar, gravel, sand, plastic granulate, animal feed, glass beads, catalysts, metal powder, etc.

Applications: Offline and online

Calibration: Features automatic calibration function, low maintenance

Software: CPAServ

Models: CPA 2-1 laboratory unit, CPA 2-1 ONLINE, INLINE

Detailed product information is available on the

CPA 2-1 product page.

What is NEXOPART A.I.?

L

Technical data for the NEXOPART CPA 2-1:

L

2. Horizontal resolution: 2927 pixels

3. Light source: LED

4. CPA Laboratory interfaces: BUS-Extension, GigE Vision, USB

5. CPA ONLINE interfaces: RS 485 (internal system, USB, GigE, Modbus TCP)

Advantages of dynamic image analysis in particle analysis

- High accuracy and reproducibility: Thousands of particles are captured in a short period of time, resulting in precise and reliable measurements.

- Real-time analysis: Dynamic image analysis provides immediate feedback, allowing for quick adjustments in the production process.

- Comprehensive shape and size measurement: In addition to particle size, complex shape parameters such as circularity, length-to-width ratio, equivalent diameter and surface roughness can also be recorded.

-

Automation and process integration: Modern systems can be seamlessly integrated into existing production lines and automate quality control.

Application in the chemical and pharmaceutical industries:

L

Optimization of analysis processes through dynamic image analysis:

L

Dynamic image analysis with NEXOPART is more than just a measurement method – it is a strategic tool for increasing your product quality, reducing errors, and optimizing industrial processes. For companies that rely on the highest product quality and maximum safety, it is an indispensable part of modern analytics.

Discover now how dynamic image analysis from NEXOPART can revolutionize your particle analysis and secure a competitive advantage with state-of-the-art measurement technology!

By the way, we also have an

unboxing video of the CPA 2-1.

FAQ about particle size and shape analysis

What is the difference between static and dynamic image analysis?

L

What are the advantages of dynamic image analysis—is it a replacement for traditional sieve analysis?

L

2. Precision: High resolution and detailed shape analysis

3. Wide measuring range: From a few micrometers to several millimeters

4. Reproducibility: Consistent results with repeated measurements